Laser Welding&Laser Cleaning Solutions

From CHINA at Competitive Price

DN laser welding is a branch of Jinan Danuo Machinery Equipments Co., Ltd. specialized in offering laser welding&laser cleaning solutions and equipments all over the world.

Innovative Laser Technology for Precision and Efficiency

Discover our cutting-edge laser welding and laser cleaning machines, designed for precise, efficient, and non-destructive processing. Watch this video to see how our products can enhance productivity and quality across various industries.

Featured Products

APPLICATION

Laser Beam Welding

Revolutionizing for Welding Industry!

Laser beam Welding is a new welding method, mainly for welding thin-walled materials and precision parts. According to TIG and MIG welding, laser welding has unbeatable advantages, with the high-speed development of laser weld tech, It will replace most traditional welding works.

Laser Welding for Commercial Catering Equipments

Laser Welding for Door&Window Frames Fabrication

Laser Welding for Bathroom Industry

Laser Welding Ship Building Industry

Laser Welding for Automobile Manufacturing

Laser Welding for Aerospace Industry

Laser Welding Semiconductor Industry

Laser Welding for Automobile Manufacturing

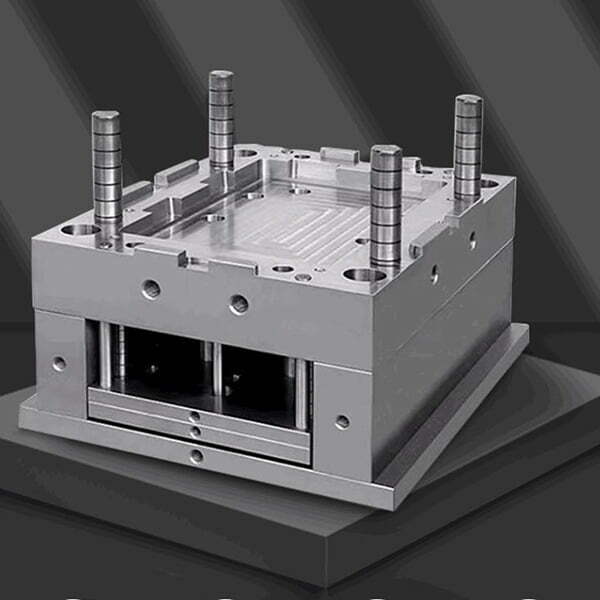

Laser Welding for Mould Fabrication

ADVANTAGES

What are the Benifits

According to Traditional TIG and MIG welding, laser beam welding has obvious advantages. Laser beam welding works more efficiently with fast speed, laser labor cost, One-time molding, and no need for secondary grinding. be available for mobile works for large and fixed metal structures and metal types of equipment, with the fast development of laser beam welding technology, laser welding will have more possibilities in the future.

More Effcient

Compared with traditional TIG and MIG welding, fast welding speed is one of the most advantages of laser beam welding. As our experience, laser welding speed is 3-5 times faster tahn MIG and 5-10 times faster than TIG. One handheld laser welder can finish work within 2 hours which a traditional welder normally costs 1 whole day.

Cost -Saving

For an initial investment, a laser beam welding machine is certainly more expensive than a traditional welder, however, the using cost is much more cost-saving. A fresh worker can handle a handheld laser welder with a very short time training, girls and elders can also handle it easily , so labor cost will be much lower instead of hiring a professional welder.

Perfect Performance

Laser beam welding performs much better than traditional welder works, the welds are beautiful and clean, deep and narrow, and no need to polish it again.

Portable for Mobile Working

Laser welders can be very samll size for easy moving, so one can take the machine to customers’ sites to do welding or repairing jobs, especially for big and fixed metal structures and types of equipment.

Untimate Possibility

With the fast development of laser beam welding technology, laser welding will have more possibilities in the future.

INVESTMENT

Estimated

Cost Analysis

The main feature that affects the price of a handheld laser welder is the power of the welder. The higher the power level, the more expensive it will be. Generally speaking, the initial investment of the laser welder is from $5500-$20,000. and the consumables include pure water and argon, it needs about 2 cans of argon if works for 8 hours.

1000W Handheld Laser Welder

Starting cost is about $5.500

1500W Handheld Laser Welder

Starting cost is about $6,500

2000W Handheld Laser Welder

Starting cost is about $7,800

1000W Handheld Laser Cleaner

Starting cost is about $5.500

1500W Handheld Laser Cleaner

Starting cost is about $6,500

2000W Handheld Laser Cleaner

Starting cost is about $7.800

Want to Know Exact Price ?

STEPS TO WORK WITH US

Ordering Laser Welding Machines

Step 1

Talk Your Project with Our Expert

You need to know extactly what you need for your project when you purchase a laser welding machine, if you are not quite clear how to choose, just talk with our sales and we will suggest you the most suitable and affordable models.

Step 2

Sample Material For Checking

Once we confirmed the model, next work is to check the welding performance for your project. You can send us your applied materials and we weld and joint them as a sample for your checking. We can make specfic changes according to the performance and your feedback.

Step 3

OEM&ODM Service

If you are Ok with our price and machine quality, then we can talk some final details about the outlooks and package. You can choose our standard models available or customsize as what you like.

Step 4

Contract Signed

We will sign and stamp the proforma invocie and contract with details confirmed on . And we can will start the production when we get the confirmed prepayment.

Step 5

Producing

Generlly it takes about 3 days to finsih and testing the machines, and delivery within 7 days. We will keep you updating the production progress so you will clear all details.

Step 6

Shipping

We will load your machine from the nearest QINGDAO port. or by Express for small and urgent spare parts. Machines will be packed by wooden box by LCL or FCL shipping.

Who We Are

DN Laser Welding is a branch of JINAN DANUO MACHINERY EQUIPMENTS CO.,LTD. We specialized in offering solutions and equipments for laser welding&laser cleaning. We can offer you professional products at competitive prices along side excellent service!

Hope we will be able to become one of your China partner in the field of laser welding and laser cleaing machines!

Get In touch

Leave us a message