A laser welder is a great choice for welding aluminum. It offers high precision and consistent results.

In this blog post, we will discuss the benefits of using a laser welder to weld aluminum, and some tips on how to get the best results.

A laser welder is a great choice for welding aluminum. It offers high precision and consistent results.

In this blog post, we will discuss the benefits of using a laser welder to weld aluminum, and some tips on how to get the best results.

Benefits of using a laser welder to weld aluminum

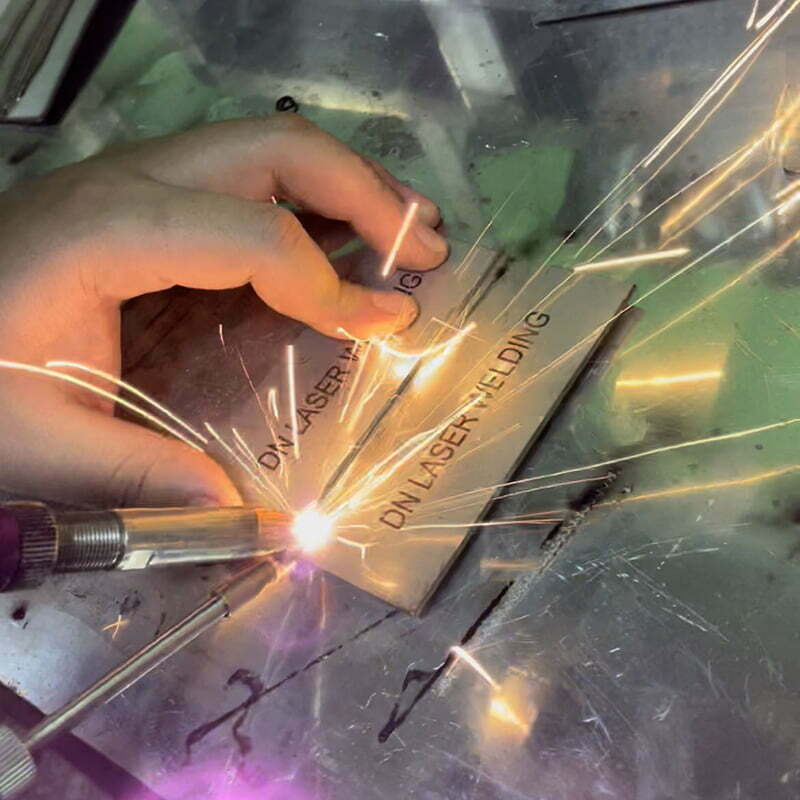

Laser welders use a high-powered laser beam to create the weld. The heat generated by the laser is carefully controlled, allowing for very precise welding of aluminum. This means that the joints created with a laser welder are strong and uniform, with no excess material or gaps between them. Laser welding also minimizes distortion, which can be an issue when welding aluminum.

The other benefit of using a laser welder is that the process is relatively fast. This means that the joint can be created quickly, allowing for high production rates and cost-effectiveness. Laser welders also require less skill than traditional welding methods to achieve consistent results.

Finally, laser welding offers a high level of safety for the operator. Since there is no need for a spark or open flame, there is less risk of fire or explosion.

Tips on how to get the best laser welding results for aluminum

When it comes to welding aluminum with a laser welder, there are some important tips that should be followed to get the best results.

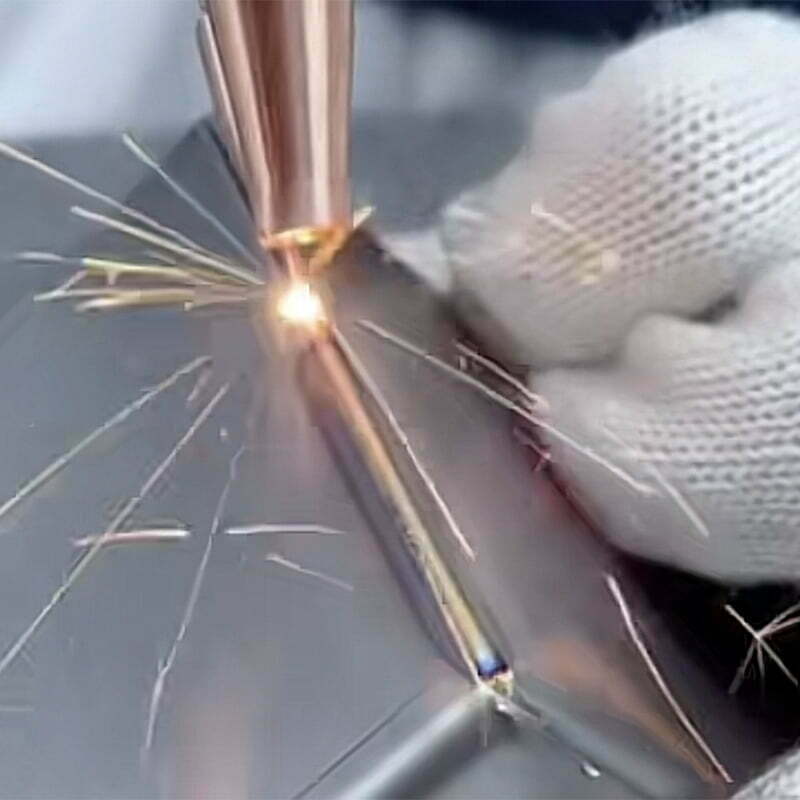

First, make sure the material being welded is clean and free from debris. Contaminates can interfere with the quality of the weld, resulting in weak joints or poor workmanship.

Second, ensure that the laser is properly calibrated before starting the welding process. This ensures that the laser is operating at its optimal power and speed settings for welding aluminum. It’s also important to choose a welding speed that is appropriate for the thickness of the material being welded.

Finally, be sure to use proper safety equipment when welding aluminum. Wear protective eye wear and use a welding mask to protect yourself from flying debris or hot metals.

Overall, laser welding is an excellent choice for welding aluminum due to its high precision and consistency, fast speed, and safety advantages. By following the tips outlined above, you can ensure that your welds are strong, uniform, and free from distortion. Thanks to these benefits, laser welding is becoming increasingly popular for welding aluminum applications.