Laser welders are advanced tools used in various industries, including jewelry making, electronics, and automotive. The cost of a laser welder depends on various factors, such as the type of laser, its power, and the manufacturer. Generally, handheld laser welders cost between $5,000 to $20,000, while industrial laser welders can range from $20,000 to over $100,000.

The type of laser can affect the cost, with fiber lasers being the most expensive due to their efficiency and precision. The power output of the laser also plays a significant role, with higher-powered lasers costing more than lower-powered ones. Additionally, the manufacturer’s reputation, customer service, and warranty can impact the price of the laser welder.

It’s essential to consider the long-term benefits of investing in a laser welder, such as increased efficiency, precision, and overall cost savings. While the upfront cost of a laser welder may seem steep, it can provide significant advantages and value in the long run.

In this article, I will talk more information about the factors that can affect the cost of a laser welder.

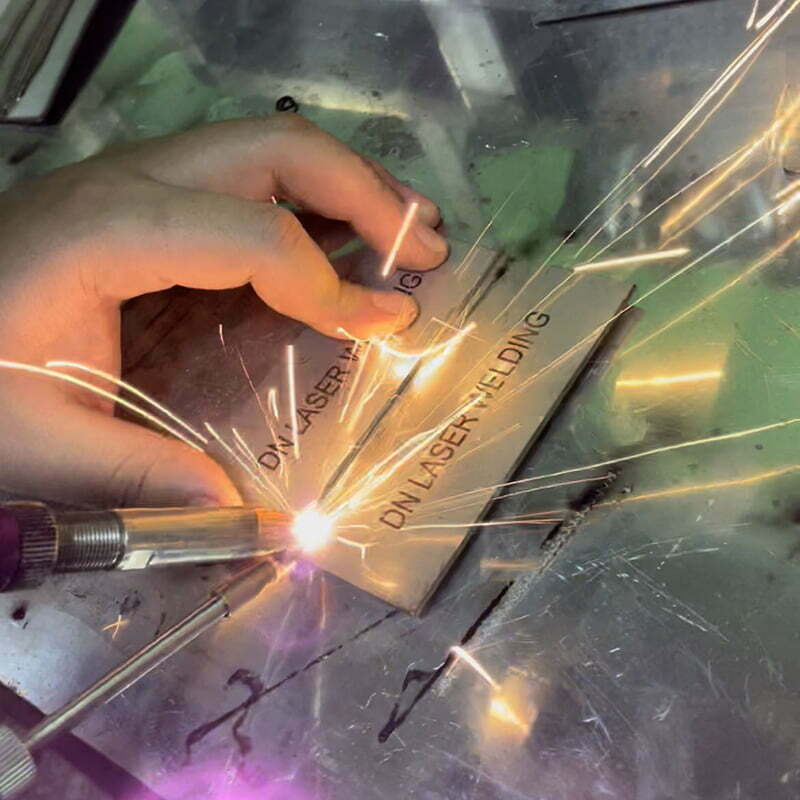

Laser welding is a high-tech process that utilizes focused light beams to join materials. This method is becoming increasingly popular in various industries, from jewelry making to medical devices to aerospace. Laser welding is precise, accurate, and efficient, making it a preferred choice over traditional welding methods. However, one major concern that most people have when it comes to laser welding is the cost of the equipment. In this article, we will explore how much a laser welder costs and what factors affect the price.

内容目录

Types of Laser Welders

Laser welders are categorized based on their laser type. The two most common types of laser welders are CO2 lasers and fiber lasers.

CO2 lasers have been around for a while and are relatively affordable compared to other types of laser welders. They are suitable for welding a wide range of materials, including plastic, metal, and glass. CO2 laser welders are best for low-power applications and are ideal for small businesses and hobbyists.

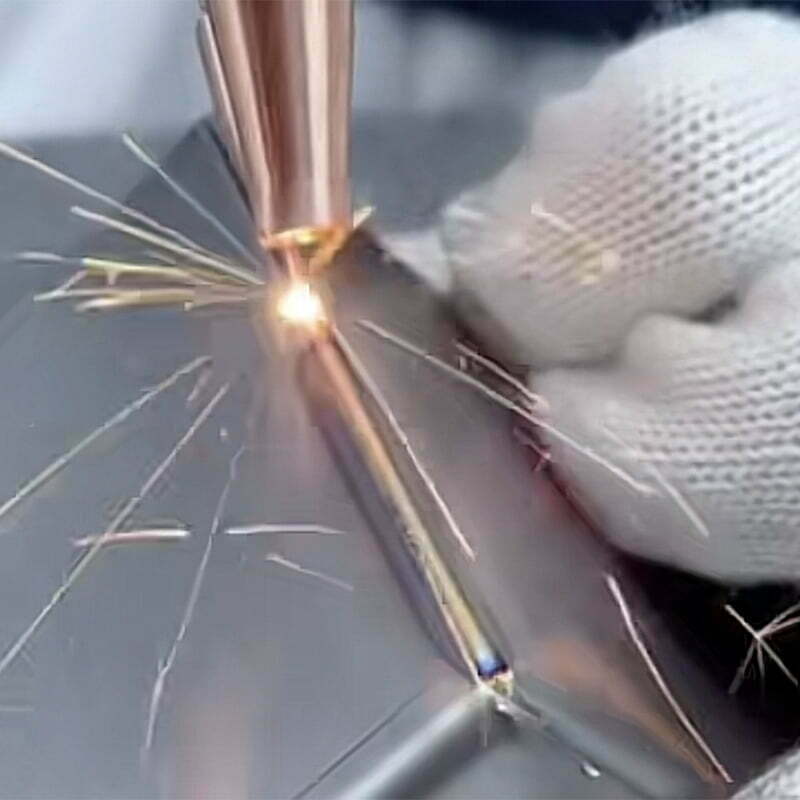

Fiber lasers are the most advanced and high-powered laser welders available in the market. They use fiber optics to generate the laser beam, making them highly efficient and precise. Fiber lasers are ideal for welding high-reflective materials like copper and brass, making them the preferred choice for industrial applications. However, they are also the most expensive laser welders.

Cost of Handheld Laser Welders

Handheld laser welders are a popular choice for small businesses and hobbyists. They are portable, easy to use, and require minimal setup time. Handheld laser welders can weld a wide range of materials, including gold, silver, and titanium. The cost of handheld laser welders ranges from $5,000 to $20,000, depending on the manufacturer and laser type.

CO2 handheld laser welders are the most affordable, with prices ranging from $5,000 to $10,000. They are suitable for welding thin metals and plastics and are ideal for small businesses and hobbyists.

Fiber handheld laser welders, on the other hand, are more expensive, with prices ranging from $10,000 to $20,000. They are ideal for welding thicker materials, including metals, and are best for industrial applications.

Factors That Affect the Cost of a Laser Welder

Several factors affect the cost of a laser welder. The following are the most significant factors that impact the price of a laser welder.

Laser Type

The laser type is one of the most significant factors that determine the cost of a laser welder. CO2 laser welders are the most affordable, while fiber lasers are the most expensive. CO2 lasers are ideal for small businesses and hobbyists, while fiber lasers are best for industrial applications.

Power Output

The power output of the laser affects the cost of the laser welder. Higher-powered lasers are more expensive than lower-powered ones. However, high-powered lasers are more efficient and can weld thicker materials, making them the preferred choice for industrial applications.

Brand and Manufacturer

The brand and manufacturer of the laser welder can affect the price. Reputable brands that have been in the market for a long time tend to have higher prices than newer brands. However, reputable brands offer better quality and customer support, making them a better investment in the long run.

Features

Laser welders come with different features that affect the cost. Some features, such as a touchscreen interface or wireless connectivity, can increase the price of the laser welder. However, these features can also improve the user experience and make the laser welder more efficient and easier to use.

Warranty and Customer Support

The warranty and customer support offered by the manufacturer can also affect the cost of a laser welder. Manufacturers that offer longer warranties and better customer support tend to charge higher prices. However, a longer warranty and better customer support can provide peace of mind and save money in the long run.

The cost of a laser welder may seem steep, but the benefits of investing in one can outweigh the initial expense. Here are some of the advantages of laser welding:

Benefits of Investing in a Laser Welder

The cost of a laser welder may seem steep, but the benefits of investing in one can outweigh the initial expense. Here are some of the advantages of laser welding:

Precision and Accuracy

Laser welding is highly precise and accurate, making it an excellent choice for industries that require high-quality welds. The focused light beam allows for precise control over the welding process, resulting in consistent and accurate welds.

Efficiency and Speed

Laser welding is faster and more efficient than traditional welding methods. The laser beam heats the material more quickly and with less heat input, resulting in faster welding times and less distortion.

Reduced Costs

Laser welding can save money in the long run by reducing material waste and improving productivity. The precision and accuracy of laser welding can reduce the need for rework, resulting in less wasted materials. Additionally, the speed and efficiency of laser welding can increase productivity, allowing for more work to be done in less time.

Versatility

Laser welding can be used to weld a wide range of materials, including metals, plastics, and glass. This versatility makes it an excellent choice for various industries, including automotive, aerospace, medical, and jewelry making.

productivity, allowing for more work to be done in less time.

Conclusion

The cost of a laser welder depends on several factors, including the type of laser, its power, the manufacturer, and the features offered. Handheld laser welders are the most affordable and are ideal for small businesses and hobbyists. Fiber laser welders are the most advanced and expensive and are best for industrial applications.

Investing in a laser welder may seem expensive, but the benefits of precision, efficiency, reduced costs, and versatility can outweigh the initial expense. When considering a laser welder, it’s essential to evaluate the long-term benefits and choose a reputable brand with good customer support and a reasonable warranty.