Laser welding has been a revolutionary technology in the welding industry. With the rise in labor costs and difficulty recruiting professional welders, Many factories who used to work with MIG and TIG welders now want laser machines. but they’re still wondering:

Does laser welding really offer a better alternative to traditional MIG or TIG? Is it better than conventional MIG and TIG welding?

The answer depends on the application. Laser welding produces welds that are stronger and more precise than arc welding, but they can only be used on thin metals. Arc welding is better for joining thicker pieces of metal together, but it doesn’t produce as strong a weld as laser welding does. Ultimately, it is up to the welder to decide which type of welding is best for the job.

In this article, I will be talking more about the the following topics related from the perspective of an experienced laser welder manufacturer.

1.Laser Welding Vs Traditional Arc Welding

2.Advantages of Laser Welding

3.Limitations of Laser Welding

4.Is Laser Welder Worthy ?

Laser welding has been a revolutionary technology in the welding industry. With the rise in labor costs and difficulty recruiting professional welders, Many factories who used to work with MIG and TIG welders now want laser machines. but they’re still wondering:

Does laser welding really offer a better alternative to traditional MIG or TIG? Is it better than conventional MIG and TIG welding?

The answer depends on the application. Laser welding produces welds that are stronger and more precise than arc welding, but they can only be used on thin metals. Arc welding is better for joining thicker pieces of metal together, but it doesn’t produce as strong a weld as laser welding does. Ultimately, it is up to the welder to decide which type of welding is best for the job.

In this article, I will be talking more about the the following topics related from the perspective of an experienced laser welder manufacturer.

1.Laser Welding Vs Traditional Arc Welding

2.Advantages of Laser Welding

3.Limitations of Laser Welding

4.Is Laser Welder Worthy ?

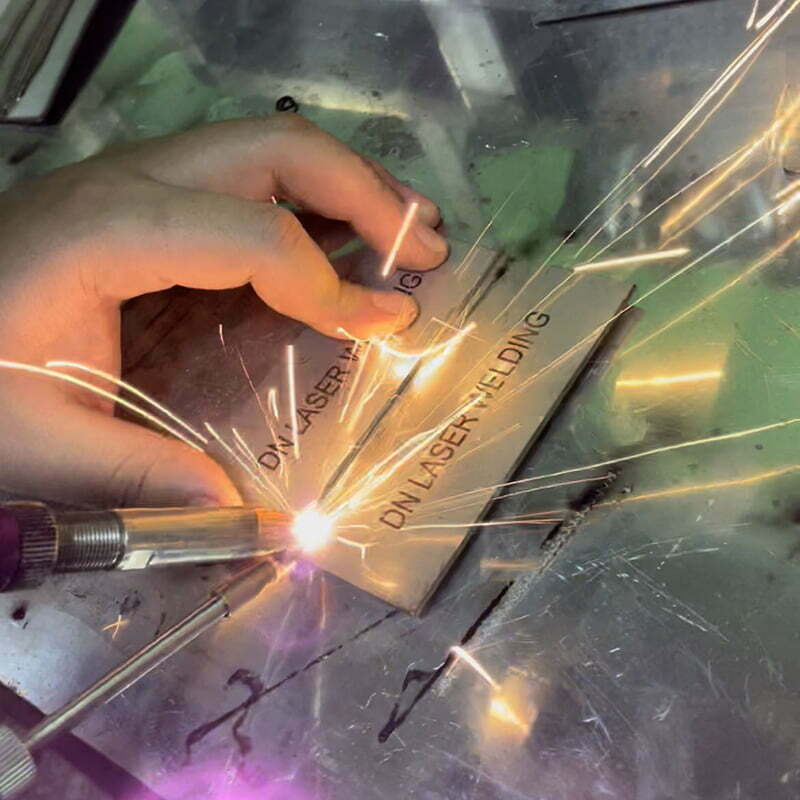

Laser Welding Vs Traditional Arc Welding

The table below I listed the pros and cons of some main welding types for your better understanding.

Type | Pros | Cons |

MIG welding – Gas Metal Arc Welding (GMAW) | MIG works well when using large or thick materials, It is the most beginner-friendly type of welding. | The MIG weld is weaker and less precise than TIG welding and Laser Welding. |

TIG welding – Gas Tungsten Arc Welding (GTAW) | TIG welding is perfect for joining small and thin materials like non-ferrous metals. The high level of precision allows you to create a wide range of joints, both inside or outside the material being worked on. | TIG welding is typically more difficult and time-consuming, with longer lead times. As a result it’s also considerably more expensive than MIG welds |

Fiber laser Welding | Fiber laser welding offers the perfect solution for those who need to weld thin material and have very precise cuts. Not only it is easier than MIG or TIG, but also stronger! | Limited to welds materials less than 6mm, and the initial equipment investment is higher than MIG and TIG welding. |

Advantages of Laser Welding

1.Quicker Welding Time

A laser welding machine can dramatically increase your productivity. This is because they are much faster than traditional welding methods. Generally speaking, laser welding is 3-5 times faster than MIG welding and 5-10 times faster than TIG welding. Further more, Laser welding can achieve one-time molding without grinding, which deceases post-processing time.

2.Cost Effective

ess labor cost, less waste and less consumables.

Labor Cost Saving-Unlike traditional welding, laser welding is super easy to operate for beginners, from our experience, one who never do welding jobs can handle a handheld laser welder within 30 mins training. Which means that you need not to hire a professional welder, and save a lot labor cost. Also as the laser welding speed is much faster, each laser welding machine can save at least 2 workers to finish the same work.

Reduced Waste– Since laser welders produce such high-quality welds, the manufacturing process produces significantly less waste.

Less Consumables- The only consumable is pure water for the cooler and argon gas.

3.Increased Strength

Laser Welding offers many benefits over traditional MIG and TIG welder use for factory production, including lower costs due to its high productivity rate with minimal need at recruitment time;

But what about quality? Is laser welding stronger than MIG and TIG ?

Laser welding has been proven to produce stronger welds than arc welding. These higher quality final products add value and increase the overall integrity of your project!

As the welding strength of laser welds is often superior to that from MIG and TIG machines. It has been seen as an attractive alternative because it can reduce labor costs while still producing high quality work

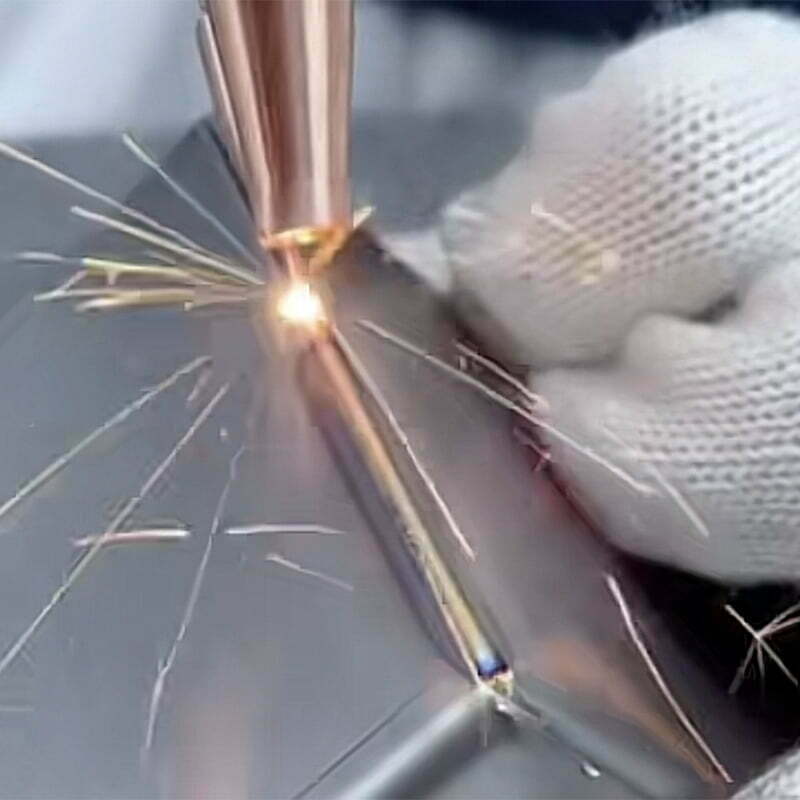

4.More Beautiful and Cleaner Welds

Laser welding produces low-heat input, which can result in deep and narrow welds with little distortion.

The laser welding process is done in a vacuum, which helps keep contaminants out of the weld and results in cleaner final products.

5. Higher Precision

Laser welding machines are highly precise and can perform delicate welds with accuracy. Because the laser is focused in a very thin beam, there are fewer chances of errors during the welding process. This allows for more precise results with tighter tolerances.

6.Non-Contact, One Sided Welding

Laser welding is a fascinating process that fuses two pieces together with laser light. This non-contact technique can create strong bonds without applying force and often only one side will be completed at once, but it’s important for root shielding on opposite sides to protect against heat damage.

7.Suitable for Wide Range Materials

Lasers can be used to weld most types of material, including steel, aluminum,and titanium. They are also able to create beautiful patterns that make them perfect for welding precious metals like gold or silver into items you want made professionally!

Extended reading: What Materials Can Be Welded by Laser Welding?

8.Versatility

-Laser welding is a versatile technique that can be used for complex shapes and high degrees of accuracy.

– It can be used for a lot of different things, from shipbuilding to hobbyist crafting (where users may not require such intricate work but still want something more than just basic seams across their projects).

-Laser welders can also be used as laser cleaners or laser cutters, simply by changing the laser gun.

-Automated welding is possible when the laser welder is connected to a robot.

9.Wider Applications

The potential applications for laser welding are endless. It can be used in industries where it wouldn’t normally occur, such as joining metal too small or delicate to handle manually – including some very specific ones like medical and flight services!

Laser welding has the potential to revolutionize many industries and make manufacturing processes much more efficient. With development of this technology, we believe there will be ultimate possibility for its applications in future!

Extended reading: What are the applications of laser welding machine?

10. Automation

This amazing laser welding machine can weld automatically when it’s connected to a robot. The operator only has to use touch screen controls to watch the progress of each job, making it easier for them in their work

11.Compact

Laser welders are typically much smaller than traditional welding machines, making them ideal for tight spaces.

12. Safe

Since laser welders don’t produce sparks or fumes, they are much safer than traditional welding methods.

Limitations of Laser Welding

There are many benefits to laser welding, but there are also several limitations to laser welding that you should consider before deciding to use it.

1.The Welding Equipment is Expensive

One of the biggest limitations of laser welding is cost. Laser welding machines are expensive, and the materials that can be welded must also be able to withstand high temperatures.

2.Welding Thickness Limited

Laser welding is generally limited to thin materials that are less than 6mm thick. Anything thicker than that will require a different welding process.

Is Laser Welder Worthy ?

Laser welding is a very precise, efficient and fast process that can be used to join materials together. It is often used in the automotive, aerospace, medical and electronics industries due to its ability to weld thin sheets of metal with minimal distortion or heat affected zone.

Fiber laser welding has a few limitations, but it’s the best option if you want your weld to be extremely precise. The initial investment may also seem high for some people who are just starting out in this field- until they realize how much less time and money will go into production with these machines!

If you are considering using laser welding for your next project, be sure to speak with a qualified technician who has experience in the field. They can advise you on what materials are best suited for the process, as well as any other tips and tricks that may help you get the most out of this technology.

We can help you too! We help customers all around the world from various industries measure their lasers. Let us know how laser welding will be used in the comment section below or email us through dn@dncnc.net and one of our staff members will get back within 24 hours.