What is a Cleaning Machine and How It Works?

Have you ever seen those commercials where someone is cleaning their car with a laser? It seems too good to be true, right? Well, believe it or not, laser cleaning machines do exist! In this blog post, we will discuss what a laser cleaning machine is and how it works.

A laser cleaning machine is a device that uses a laser to clean surfaces. The laser beam is used to remove dirt, dust, and other contaminants from the surface. The machine can be used to clean a variety of surfaces, including metal, plastic, glass, and ceramics. In the following, we will discuss how a laser cleaning machine works and highlight some of its key benefits!

A laser cleaning machine uses a high-intensity beam to remove dirt, dust, and other contaminants from the surface without harming the material. The beam is focused on the surface and creates a reaction that breaks down the particle bonds and then vaporizes them. This process is often referred to as “ablation” because it removes only a certain layer of material.

The laser beam is adjustable in terms of power, frequency, and pulse width. This allows the user to adjust the cleaning process for different materials and surface conditions. Additionally, multiple passes can be used to ensure a thorough clean. For example, a two-pass process could be used on a glass window: one pass to remove the dirt and dust, and a second to refine the surface.

The main benefits of using a laser cleaning machine are speed, accuracy, and safety. The process is much faster than traditional methods such as scrubbing or sanding and can be completed in just minutes. Furthermore, it is highly accurate and there is no risk of damaging the surface. Finally, the process is safer than using chemicals as there are no fumes or residue left behind.

In conclusion, a laser cleaning machine is an efficient and safe way to clean any type of surface. It can be used on a variety of materials and offers fast, accurate results with little risk of damaging the material. If you are looking for an effective and safe way to clean surfaces, a laser cleaning machine may be a perfect choice.

For more information on laser cleaning machines and how they work, contact a professional today! They can help you decide if a laser cleaning machine is a right choice for your project. https://dnlaserwelding.com/laser-cleaning-machine/

Have you ever seen those commercials where someone is cleaning their car with a laser? It seems too good to be true, right? Well, believe it or not, laser cleaning machines do exist! In this blog post, we will discuss what a laser cleaning machine is and how it works.

A laser cleaning machine is a device that uses a laser to clean surfaces. The laser beam is used to remove dirt, dust, and other contaminants from the surface. The machine can be used to clean a variety of surfaces, including metal, plastic, glass, and ceramics. In the following, we will discuss how a laser cleaning machine works and highlight some of its key benefits!

A laser cleaning machine uses a high-intensity beam to remove dirt, dust, and other contaminants from the surface without harming the material. The beam is focused on the surface and creates a reaction that breaks down the particle bonds and then vaporizes them. This process is often referred to as “ablation” because it removes only a certain layer of material.

The laser beam is adjustable in terms of power, frequency, and pulse width. This allows the user to adjust the cleaning process for different materials and surface conditions. Additionally, multiple passes can be used to ensure a thorough clean. For example, a two-pass process could be used on a glass window: one pass to remove the dirt and dust, and a second to refine the surface.

The main benefits of using a laser cleaning machine are speed, accuracy, and safety. The process is much faster than traditional methods such as scrubbing or sanding and can be completed in just minutes. Furthermore, it is highly accurate and there is no risk of damaging the surface. Finally, the process is safer than using chemicals as there are no fumes or residue left behind.

In conclusion, a laser cleaning machine is an efficient and safe way to clean any type of surface. It can be used on a variety of materials and offers fast, accurate results with little risk of damaging the material. If you are looking for an effective and safe way to clean surfaces, a laser cleaning machine may be a perfect choice.

For more information on laser cleaning machines and how they work, contact a professional today! They can help you decide if a laser cleaning machine is a right choice for your project. https://dnlaserwelding.com/laser-cleaning-machine/

Main Types of Laser Cleaning Machines

If you are in the market for a laser cleaning machine, it is important to understand the basics of these machines before making a purchase. In this part, we will discuss the three main types of lasers used in cleaning machines, as well as some of the benefits and drawbacks of each type. We will also provide an overview of how laser cleaning machines work, and explain some of the factors you should consider when choosing a machine for your business.

Laser cleaning machines use lasers to remove residues such as oil, grease, dust, and dirt from surfaces. The most common types of lasers used in these machines are CO2 lasers, Nd: YAG lasers, and fiber laser cleaners.

CO2 lasers emit a 10.6-micron wavelength that is well suited for removing organic matter, such as oil and grease. This type of laser is typically used for cleaning industrial machinery, tools, and hard surfaces.

Nd: YAG lasers emit a 1.064-micron wavelength that is ideal for removing inorganic material, such as rust and scale. This type of laser is commonly used in the automotive, electronics, and medical industries.

Fiber laser cleaning systems feature a pulsed fiber laser that is used to remove metal oxides from metal components. This type of laser is typically used for surface preparation in industrial applications.

All three types of lasers offer several benefits for cleaning processes, including fast removal times, precise cleaning, no damage to substrates, and low energy consumption. However, each type of laser has its own set of drawbacks as well. For example, CO2 lasers are limited in terms of their power output and require more maintenance than other types; Nd: YAG lasers emit a very high-intensity beam that can cause eye damage if not used properly, and fiber lasers are expensive and can be difficult to operate.

When choosing a laser cleaning machine, it is important to consider the type of material being cleaned, the size of the area to be cleaned, and the budget available for the purchase. Additionally, it is important to evaluate each type of laser in terms of its power output, maintenance requirements, and safety features. By understanding the basics of laser cleaning machines and considering these factors, you can make an informed decision about the best machine for your business.

By learning more about the different types of lasers used in laser cleaning machines and how they work, you can make sure that you choose the right machine for your business. With the right machine, you can achieve quick and effective cleaning results that will help to keep your operations running smoothly.

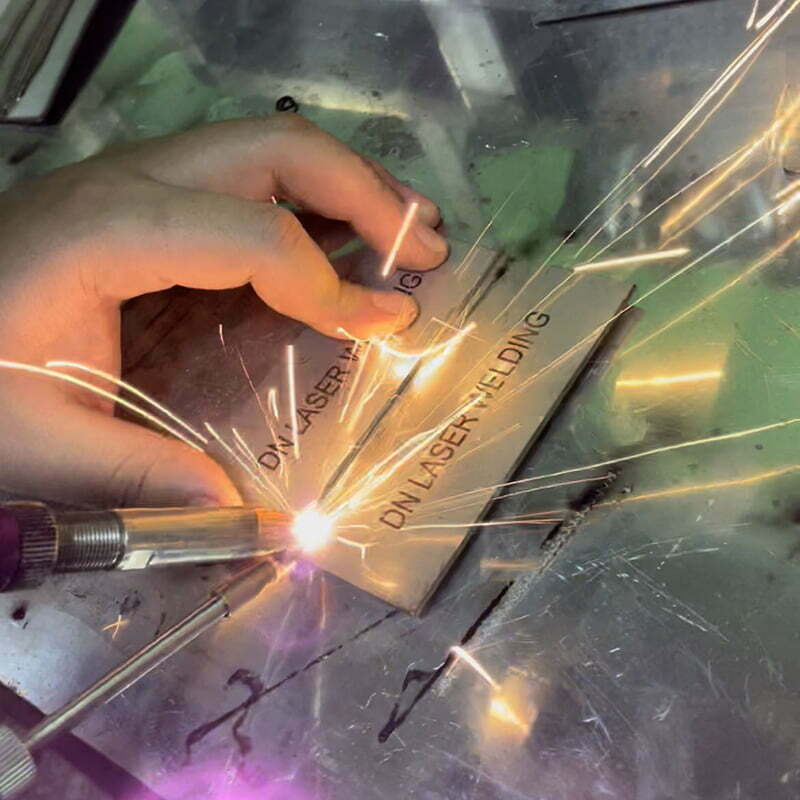

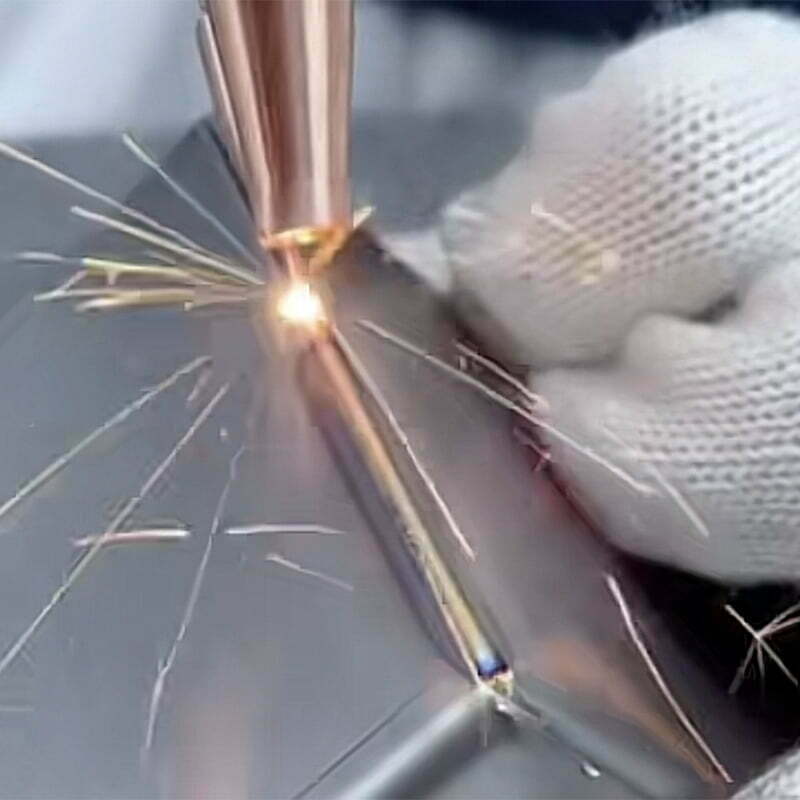

The Basics of Fiber Laser Welding Machine

A fiber laser cleaning system typically consists of three main parts: the laser generator, the optics box, and the workbench. The laser generator creates the laser beam, which is then directed through the optics box to the workbench. The optics box focuses the beam and shapes it into the desired pattern, while the workbench provides a stable surface for cleaning.

In addition to these main components, fiber laser cleaners also include several additional parts that are used to control and monitor the cleaning process. These include a power supply, a cooling unit, an exhaust system, and a controller unit. The power supply provides electrical power to the laser generator, while the cooling unit ensures that the optics box remains at a safe temperature. The exhaust system removes unwanted fumes and particles from the work area, and the controller unit allows you to adjust various settings on the machine.

When purchasing a laser cleaning machine, it is important to consider the type of material being cleaned, the size of the area to be cleaned, and the budget available for purchase. Additionally, it is important to evaluate each type of laser in terms of its power output, maintenance requirements, and safety features. By understanding the basics of how laser cleaners work and considering these factors, you can make an informed decision about the best laser cleaning machine for your business. With the right machine, you can achieve quick and effective cleaning results that will help to keep your operations running smoothly.

From Glass to Metal – The Many Surfaces a Laser Cleaning Machine Can Handle

If you’re in the market for a laser cleaning machine, you might be wondering what surfaces it can clean. There are many different materials that a laser cleaning machine can handle, including glass, metal, and even plastic! In this blog post, we’ll take a closer look at each of these materials and discuss how a laser cleaning machine can help clean them.

When it comes to glass, a laser cleaning machine is a perfect choice for removing stubborn dirt and grime. Its powerful beam of light can penetrate deep into the material and precisely target contaminants with pinpoint accuracy. The laser not only cleans the surface quickly but also leaves behind an even finish without any smearing or streaking. Plus, since the laser is gentle on glass surfaces, it’s safe to use on delicate items like spectacles and windows.

Metal surfaces can benefit from the power of laser cleaning as well. With a single pass of the machine’s beam, grease, rust, oil, and other debris can be quickly removed without damaging the surface. Laser cleaning is also effective at removing corrosion and oxidation on metal surfaces, leaving them looking like new. This makes laser cleaning an excellent choice for maintaining machinery and restoring vintage metals.

Cleaning brick is a difficult job. It can be tough to remove all the dirt, dust, and grime that accumulates on them, not to mention the stains that can be difficult to remove. That’s where laser cleaning comes in. A laser cleaning machine can quickly and easily remove all the built-up dirt and debris from your brick surfaces, leaving them looking clean and new. In addition, the laser can also remove stains and discoloration, leaving your brick looking like new.

Finally, a laser cleaning machine can safely clean plastic surfaces as well. With its targeted beam of light, it can easily remove dirt, dust, and other residues that build up on plastic surfaces over time. The laser is gentle enough to clean plastic without causing any damage or discoloration.

All in all, a laser cleaning machine offers an effective and safe way to clean many different materials. From glass and metal to plastic, it can help restore surfaces to their original condition and leave them looking like new. Whether you need to clean your windows, metal machinery, brick walls, or plastic items, a laser cleaning machine can help you get the job done quickly and efficiently.

How a Laser Welding Machine Will Benefit your business?

If you’re looking for an efficient and reliable way to clean your business premises, laser cleaning may be the perfect solution. This innovative technology offers several benefits that can help improve your operations. In this article, we’ll take a closer look at what laser cleaning is and how it can benefit your business.

Laser cleaning is an advanced form of technology that utilizes the power of lasers to remove contaminants from surfaces. It is a non-contact method, meaning it won’t damage or corrode the surface being cleaned. Laser cleaning uses high-energy beams that vaporize dirt and debris with pinpoint accuracy. This process eliminates dust, grease, oil, paint, rust, and other types of contaminants without damaging the surface being cleaned.

The main benefits of laser cleaning include improved productivity and reduced labor costs. Laser cleaning is fast and efficient, allowing your workers to clean large surfaces quickly and easily. This can save time, money, and effort that would otherwise be spent on manual methods such as scrubbing and scraping. Furthermore, laser cleaning is often more effective than manual methods at removing stubborn contaminants.

Another benefit of laser cleaning is improved safety. Unlike other methods, laser cleaning eliminates the need for harsh chemicals or abrasive materials that can damage surfaces or cause health risks to workers. This reduces the risk of workplace accidents and ensures a safe environment for everyone.

Finally, laser cleaning can save your business money in the long run. It is a cost-effective solution that reduces labor costs and eliminates the need for replacement parts or frequent maintenance. This means you can save money on repairs and replacements while still maintaining clean surfaces.

All in all, laser cleaning is an innovative technology that can benefit your business in many ways. It is fast, efficient, and cost-effective, making it an ideal solution for cleaning surfaces quickly and effectively. If you’re looking for a reliable way to keep your premises clean, laser cleaning is a perfect choice. With its many benefits, it can help improve the efficiency and safety of your operations. So don’t wait any longer – explore the benefits of laser cleaning today! https://dnlaserwelding.com/laser-cleaning-machine/

10 Tips for Choosing a Laser Cleaning Machine Supplier in China

If you’re looking for a laser cleaning supplier, China is definitely the place to be. With so many options available, it can be tough to know which one is right for your business. That’s why we’ve put together this list of 10 tips to help you choose the best supplier for your needs. Keep reading to learn more!

- Research different laser cleaning suppliers – Do your research to compare prices, services, and customer reviews so you can make an informed decision when it comes time to buy.

- Check the supplier’s quality standards – Make sure they are up-to-date and certified following industry standards such as ISO 9001.

- Consider the supplier’s customer service – Ask about their responsiveness and communication style; are they easy to get in touch with?

- Confirm the supplier’s production capacity – Make sure they can meet your company’s needs, now and in the future.

- Compare prices between suppliers – It’s important to compare prices between different laser cleaning suppliers so you can get the best deal for your money.

- Make sure the supplier is experienced – Check that they have experience working with clients in your industry so they understand your needs and can provide the right solutions.

- Ask about financing options – Find out what kind of payment options and financing plans the supplier offers so you can work out a plan that best suits your budget.

- Look for additional services – Some suppliers may offer extra services such as maintenance, repairs, or upgrades to help keep your equipment in top condition.

- Consider the location of the supplier – If you’re buying from overseas, make sure the supplier is located close enough for fast delivery times.

- Read online reviews – Finally, take a look at online reviews to see what other customers are saying about the laser cleaning supplier in question. This will give you an idea of their quality of service and reliability.

By following these tips, you can rest assured that you’re choosing the best laser cleaning supplier for your business in China.

If you’re interested in learning more about our laser cleaning products, please call us today. We would be happy to discuss your specific needs and provide you with a free quote. We look forward to working with you! https://dnlaserwelding.com/laser-cleaning-machine/

How to Use a Laser Cleaning Machine for the Best Results

When it comes to cleaning, there is no one-size-fits-all solution. What works for one surface may not work for another, and what works for one type of dirt may not work for another. That’s why it’s important to know how to use a laser cleaning machine properly. In this blog part, we will discuss the best ways to use a laser cleaner and get the best results!

First, it’s important to familiarize yourself with the different laser cleaning settings. Laser cleaners come with different power settings and focal lengths. Choose the appropriate settings for your specific application – consider the size of the area you are cleaning, the type of dirt on the surface, and any other factors that may affect your results.

Second, make sure you use safety precautions. Laser cleaning machines can be dangerous when not used correctly, so it’s important to wear protective equipment such as goggles and gloves to protect yourself from the laser beam or any potential debris that may be thrown off during the cleaning process.

Third, know how to position your laser cleaner for the best results. The laser beam should be aimed directly at the surface you are trying to clean, and it’s important to keep the focus on a single spot while cleaning. This will ensure that the dirt is removed effectively without damaging the underlying material.

Finally, use an appropriate cleaner for your specific application. Different surfaces may require different cleaners, so make sure to read the instructions on your laser cleaner or consult a professional before using it.

By following these tips, you can make sure that you are using your laser cleaning machine correctly and getting the best results possible. Remember to always follow safety guidelines when operating a laser cleaning machine and use an appropriate cleaner for the surface being cleaned. With proper technique and the right cleaning solutions, you can get your surfaces looking as good as new in no time.

Happy Cleaning!^-^ https://dnlaserwelding.com/laser-cleaning-machine/