What is Laser Welding Machine and How it Works?

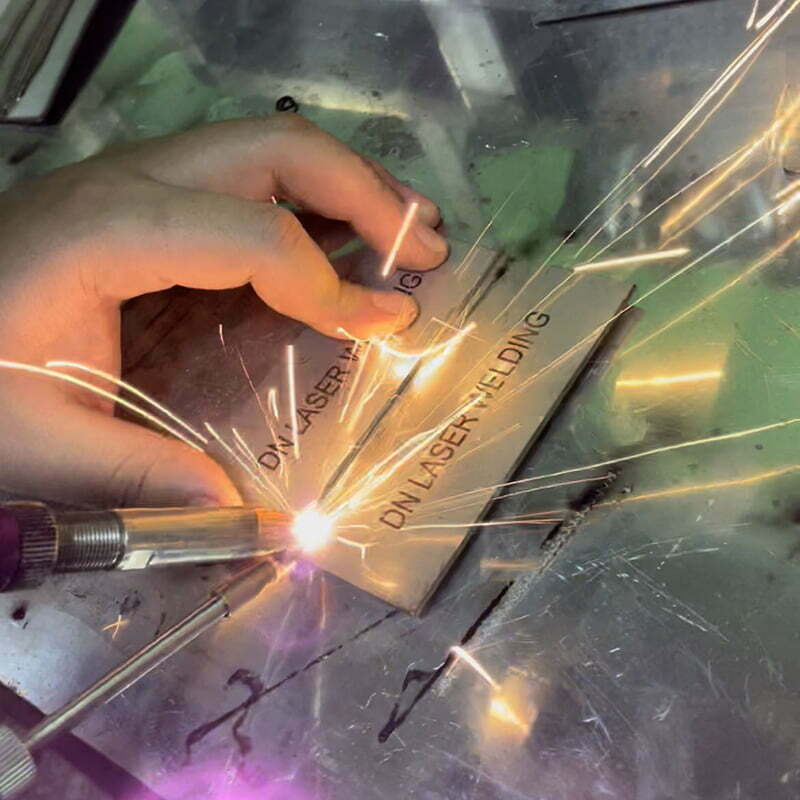

If you are looking for a welding machine that offers high precision and quality, then you may want to consider investing in a laser welding machine. This type of machine uses a concentrated beam of light to fuse two pieces of metal together. In this blog post, we will provide an introduction to laser welding and discuss how it works.

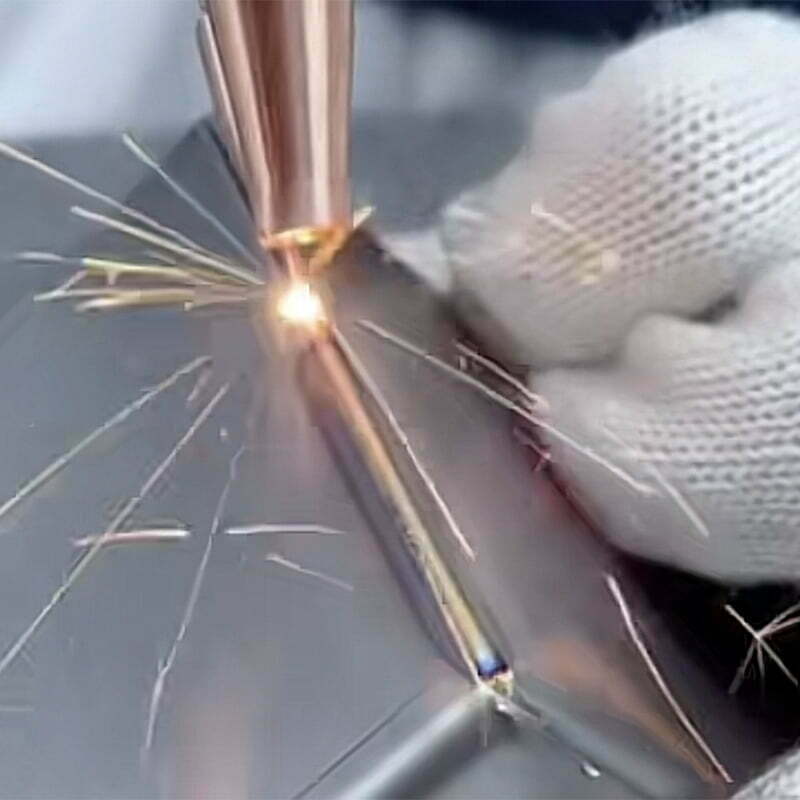

Laser welding machines are composed of three main components: a laser source, optics, and a focus lens. The laser source produces the light beam which is then channeled through the focus lens. This focuses the beam in one specific area, allowing it to be directed at a precise point on the material being welded.

The optics control the direction of the beam and keep it centered on the desired location.

When using a laser welder, temperatures can reach up to 13,000 degrees Fahrenheit in a matter of seconds. This makes it ideal for welding materials with high melting points such as stainless steel and aluminum alloys. The laser also allows for extremely small and intricate welds that would be impossible to achieve with traditional welding methods.

Additionally, laser welding is a clean and efficient process as there are no fumes or sparks flying around the area. It also offers much higher levels of accuracy than other types of welding machines, allowing for precise welds with minimal distortion.

Overall, laser welding machines are a great choice for anyone looking for a fast, efficient and precise welding process. From creating precision welds to welding metals with high melting points, laser welding offers numerous advantages that make it an ideal choice for many manufacturing applications. Thanks to its strong beam of light, laser welding machines can provide extremely accurate results with minimal distortion. With its clean operation and high levels of accuracy, it is easy to see why laser welding machines are becoming increasingly popular in a wide range of industries.

This concludes our introduction to laser welding and how it works. With its impressive speed, accuracy and clean operation, laser welding machines are an ideal choice for anyone looking for a reliable and efficient welding process. If you’re considering investing in one of these machines, be sure to explore all of the available options in order to find the one that best suits your needs.

If you are looking for a welding machine that offers high precision and quality, then you may want to consider investing in a laser welding machine. This type of machine uses a concentrated beam of light to fuse two pieces of metal together. In this blog post, we will provide an introduction to laser welding and discuss how it works.

Laser welding machines are composed of three main components: a laser source, optics, and a focus lens. The laser source produces the light beam which is then channeled through the focus lens. This focuses the beam in one specific area, allowing it to be directed at a precise point on the material being welded.

The optics control the direction of the beam and keep it centered on the desired location.

When using a laser welder, temperatures can reach up to 13,000 degrees Fahrenheit in a matter of seconds. This makes it ideal for welding materials with high melting points such as stainless steel and aluminum alloys. The laser also allows for extremely small and intricate welds that would be impossible to achieve with traditional welding methods.

Additionally, laser welding is a clean and efficient process as there are no fumes or sparks flying around the area. It also offers much higher levels of accuracy than other types of welding machines, allowing for precise welds with minimal distortion.

Overall, laser welding machines are a great choice for anyone looking for a fast, efficient and precise welding process. From creating precision welds to welding metals with high melting points, laser welding offers numerous advantages that make it an ideal choice for many manufacturing applications. Thanks to its strong beam of light, laser welding machines can provide extremely accurate results with minimal distortion. With its clean operation and high levels of accuracy, it is easy to see why laser welding machines are becoming increasingly popular in a wide range of industries.

This concludes our introduction to laser welding and how it works. With its impressive speed, accuracy and clean operation, laser welding machines are an ideal choice for anyone looking for a reliable and efficient welding process. If you’re considering investing in one of these machines, be sure to explore all of the available options in order to find the one that best suits your needs.

Arc Welding vs Laser Welding: Which Is Best for Your Project?

When it comes to welding, there are a few different options that you can choose from. Arc welding and laser welding are two of the most common methods, but which one is best for your project? In this blog part, we will discuss the pros and cons of each type of welding and help you decide which one is right for you!

Arc welding is one of the oldest and most commonly used types of welding. It uses an electric current to create an arc between two pieces of metal, which produces high temperatures to fuse them together. This method can be done without any additional tools, making it a great choice for DIY projects.

Pros:

• Easy to use

• Inexpensive

• Available in various sizes and power levels

Cons:

• Not as precise as laser welding

• Requires more skill and experience to use successfully

• High temperatures can cause metal warping or damage nearby materials

Laser welding is a newer technology that uses a focused heat source to weld two pieces of metal together. It has become increasingly popular in the welding industry due to its high precision and superior performance.

Pros:

• Highly precise

• Minimal heat distortion

• Can be used with a wide range of material

• Quicker than traditional welding

Cons:

• More expensive than arc welding

• Requires specialized equipment and skills to use effectively

Overall, both arc welding and laser welding have their advantages and disadvantages. Depending on the type of project you are working on, one may be better suited than the other. If precision is a priority, then laser welding may be the best option for you. However, if you are working on a DIY project and don’t need complex welds, then arc welding can be a great choice. Ultimately, it is up to you to decide which type of welding will work best for your specific project.

No matter which type of welding you choose to use, it is important to ensure that you have the right safety equipment and take all necessary precautions while operating. With the right tools and knowledge, welding can be an incredibly rewarding experience!

This blog post has discussed the pros and cons of both arc welding and laser welding, helping you decide which is best for your project. No matter which type you choose, it is important to always work with safety in mind and use the proper tools and techniques for a successful weld. With the right approach, you can enjoy the rewards of welding and create beautiful projects.

If you’re looking for a high-quality laser welding machine, then look no further than our selection of products here at DN Laser Welding. We offer some of the best machines on the market, and our team of experts is available to help you choose the right one for your needs. Contact us today to learn more! Source: https://dnlaserwelding.com/laser-welding-machine/

How Much Does a Laser Welding Machine Cost?

There are a lot of factors to consider when purchasing a laser welding machine. The cost is obviously one of the most important, but there are other things to think about as well. In this part, we will take a look at some of the things you need to keep in mind when purchasing a laser welding machine. We will also provide an estimate of how much these machines typically cost. So, if you’re thinking about purchasing a laser welding machine, keep reading!

When it comes to the cost of a laser welding machine, there are several components that need to be taken into consideration. Firstly, the size and type of machine you choose will have an impact on the price. For example, a larger machine with more power will typically come at a higher price tag than a smaller or less powerful model. Additionally, you’ll want to look at the features and functions that come with the machine. Are there any extras that you may not need but they offer? If so, then this could increase your total cost.

Another important factor to consider is whether or not the laser welding machine comes with a warranty. Many companies provide warranties for their machines, and this can help to protect your investment in the event of any malfunctions or damage. If a warranty is not included with the machine, then you may want to consider purchasing one separately.

Finally, it’s important to factor in installation and delivery costs for the welding machine. This will vary depending on where you purchase it from, as well as how far away the delivery destination is. It’s important to take these costs into account when budgeting for your machine, so you can ensure that it won’t exceed your budget.

When all of the above factors have been taken into consideration, a laser welding machine typically costs anywhere between $4500 and $20000, depending on the size, features, and quality of the machine. Other prices may be higher or lower, depending on your needs, so it’s important to do some research and compare different models before making a decision.

Purchasing a laser welding machine can be a significant investment for any business, but with careful consideration and research, you can ensure that you get one that suits you and a warranty that is included. Of course, this price could vary significantly depending on the exact model you choose and any additional costs associated with it.

To sum up, a laser welding machine can be quite expensive. However, if you shop around and make sure to consider all of the factors mentioned above, you should be able to find one that fits your needs and budget. It’s important to do some research before making a purchase, so you can ensure that you get the best value for your money. Source: https://dnlaserwelding.com/laser-welding-machine/

7 Materials a Laser Welding Machine Can Weld

A laser welding machine can weld a variety of materials. In fact, there are quite a few different materials that these machines can work with. Here is a list of some of the most common materials that laser welding machines can weld:

-Steel

-Aluminum

-Copper

-Brass

-Nickel alloys

-Gold alloys

-Titanium alloys

Laser welding machines are capable of producing extremely precise welds. This makes them ideal for applications that require high levels of accuracy, such as in the medical and aerospace industries. In addition to welding materials together, laser welding can also be used to join different types of metals without melting the base material.

In addition to the materials listed above, laser welding machines can also weld plastic and other non-metallic materials. However, these types of welds require more time and experience to be successful due to the different properties of each material.

No matter what type of material you need to weld, a laser welding machine can provide you with precision and accuracy. With the right technique and knowledge, you can create strong and reliable welds in a variety of materials. Whether it’s steel, aluminum, copper, brass, or any other type of metal, laser welding can get the job done quickly and efficiently. So if you need to weld something together, don’t forget to look into laser welding as an option. You won’t be disappointed.

Wide Applications of Laser Welding Machine

The laser welding machine has been widely used in many industries. It is an important piece of equipment in modern manufacturing. The wide applications of laser welding machines are mainly due to their advantages such as high efficiency, low cost, and good weld quality. In this article, we will discuss the main applications of laser welding machines in various industries.

The automotive industry is the largest user of laser welding machines. Automobiles need to be welded and assembled together with precise accuracy and this is where a laser welding machine comes into play. The laser beam can melt even highly resistant materials like stainless steel, aluminum, and titanium in a matter of seconds. This has made it easier for automobile manufacturers to reduce production costs and improve the quality of their vehicles.

The laser welding machine is also used in the aerospace industry. It is used to weld components made from materials such as titanium, stainless steel, aluminum, and copper alloys. The high accuracy of the laser beam ensures that parts are perfectly joined together without any gaps or uneven areas. This helps to ensure the safety of the aircraft and its passengers.

Another industry that heavily relies on laser welding machines is the medical device manufacturing industry. These machines are used to weld implantable devices such as pacemakers, hearing aids, stents, and prosthetics with great precision. The accuracy provided by the laser beam ensures that these devices are perfectly sealed and safe to use.

The construction industry also benefits from the use of laser welding machines. These machines can be used to weld steel girders, beams, and other structural components with precision and accuracy. The machine is also able to work on large surface areas without any problems due to its high power output.

The food and beverage industry also uses laser welding machines for sealing packages. The heat generated by the laser beam seals packages quickly and accurately, ensuring that food is kept fresh for longer.

Finally, the jewelry industry relies heavily on laser welding machines. These machines can be used to weld precious metals like gold, silver, platinum, and brass with precision and accuracy. This ensures that jewelry pieces are perfectly crafted without any flaws or imperfections.

In conclusion, laser welding machines have wide applications across many industries due to their high efficiency, low cost, and good weld quality. Automotive, aerospace, medical device manufacturing, construction, food and beverage, and even the jewelry industry. These machines are essential for many businesses today.

If you are looking for a reliable and high-quality laser welding machine, then please contact us. We offer a wide range of laser welding machines that are perfect for any industry. We also provide excellent customer service and support so you can be sure that you are making the right decision.

10 Tips for Choosing the Right Laser Welding Machine

If you’re in the market for a laser welding machine, it can be difficult to know where to start. With so many different brands and models available, how do you choose the right one for your needs? In this part, we will provide 10 tips for choosing the right laser welding machine. By following these guidelines, you can find a machine that meets your specific requirements and helps you achieve your welding goals.

1. Analyze Your Requirements: Before you begin your search, take some time to analyze the requirements of your project. Consider factors such as type of material, size and shape of workpiece, welding technique required (e.g., spot- or seam-welding), and desired output power. This will help narrow down the range of machines that are suitable for your project.

2. Consider Your Budget: Once you have identified the minimum requirements of your project, you need to consider its budget. Keep in mind that while laser welding machines can be expensive, there are also plenty of models available at various price points. Decide on a reasonable budget before you start shopping.

3. Research the Market: Knowing what’s available in the market will help you make a more informed decision. Do some research and read product reviews of different laser welding machines to get an idea of their features, performance, and quality. This will give you a better understanding of the options available to you so that you can make an informed choice.

4. Find a Reliable Supplier: The next step is to find a reliable supplier of laser welding machines. Ensure that the company you choose has a good track record in terms of providing quality products and excellent customer service.

5. Take Expert Advice: If you’re still unsure which machine to buy, take expert advice. Speak to a professional who specializes in laser welding to get their opinion on the different machines available. They can provide valuable insight into which model will best meet your needs.

6. Ask for Demonstrations: Before you make your final decision, ask for demonstrations of the machines you are considering. This will help you get a better feel for the equipment and ensure that it is up to the task.

7. Consider Efficiency: Laser welding machines come with different efficiency ratings, so make sure you look for one that has a good rating. A more efficient machine will save time and money by getting the job done faster and with fewer errors.

8. Choose Quality Parts: The components of the laser welding machine should be of high quality. Look for models that are made from durable and corrosion-resistant materials, such as aluminum or stainless steel.

9. Choose a Machine with Automation: Automation is key when it comes to laser welding machines. Look for one that has an integrated vision system and automated controls so that you can execute your jobs more quickly and accurately.

10. Consider Training: Finally, consider the amount of training that will be required to use the machine properly. If you are new to laser welding, ask if the supplier provides on-site training or technical support. This could help you get up and running quickly and make sure that you’re getting the most out of your machine.

By following these tips, you can find a laser welding machine that is right for your project and meets all of your requirements. With the right machine, you can achieve great results with minimal effort and expense.

If you are in the market for a laser welding machine, visit our website today to learn more about our products and services. Our experts can help you find the best machine for your needs and provide you with all the training and support you need to get started.

How to Use a Laser Welding Machine

Before you can start using one, there are some things you need to know. In this part, we will discuss the basics of how to use a laser welding machine. We’ll cover everything from setting up the machine to welding different types of materials. By the end of this post, you’ll be ready to start using your laser welding machine like a pro!

First, you’ll need to make sure your machine is properly installed and connected. Before using the machine, read through the instruction manual and follow its instructions for setup. When everything is ready, turn on the machine and wait for it to heat up. Once the correct temperature has been reached, you can move on to welding.

Now that the machine is ready to use, you’ll need to select the right welding parameters. Depending on the material and application, you’ll need to change settings like current, mode of operation, weld pattern, pulse duration, and more. Once all of your settings are in place, you’re ready to start welding.

When it comes to welding, safety is always the number one priority. Make sure to wear protective gear like gloves, goggles, and a face shield when using the machine. Additionally, make sure that all of your connections are secure before you begin welding. Once everything is in place, you can start welding the materials together.

Welding with a laser welding machine is a precision process. It can take some practice to get the hang of it, but once you master the technique you’ll be able to create reliable and strong welds in no time. To ensure that your welding job turns out as expected, be sure to keep an eye on the material while welding and monitor any flaws or defects.

Using a laser welding machine is not only a great way to produce strong, reliable welds, but it can also save you time and money. With the proper setup and training, anyone can learn how to use this powerful tool. Now that you know the basics of how to use a laser welding machine, you’re ready to start creating awesome and durable welds. Good luck!

References: https://dnlaserwelding.com/laser-welding-machine/