For decades, the automotive industry has relied on traditional welding methods to assemble car parts. These methods, however, have become outdated. Today, laser welding is becoming increasingly popular in the automotive industry due to its efficiency and precision. Let’s take a look at how laser welding works and why it is beneficial for the automotive industry.

What is Laser Welding?

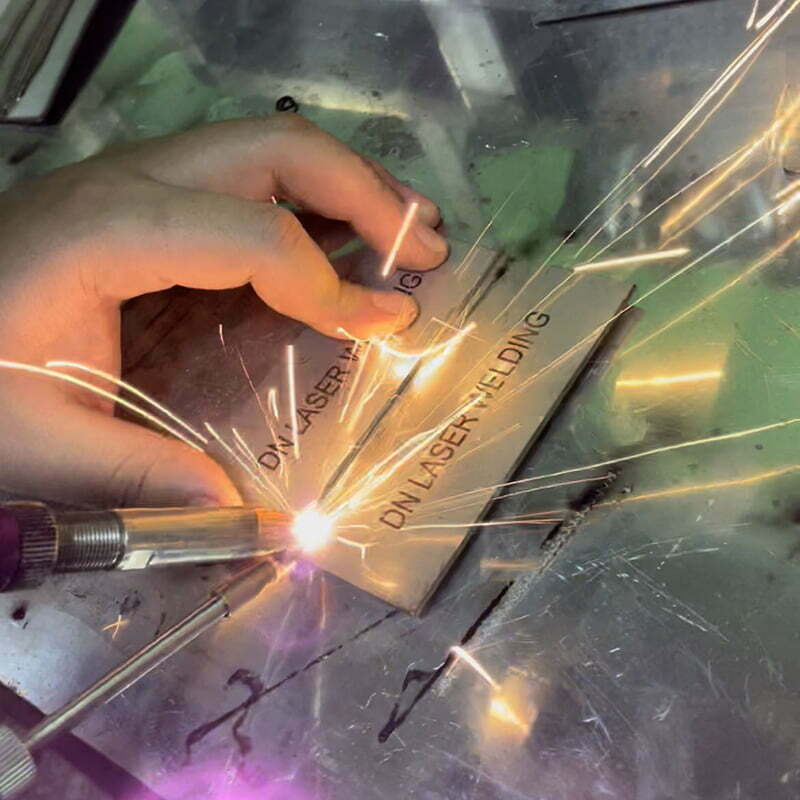

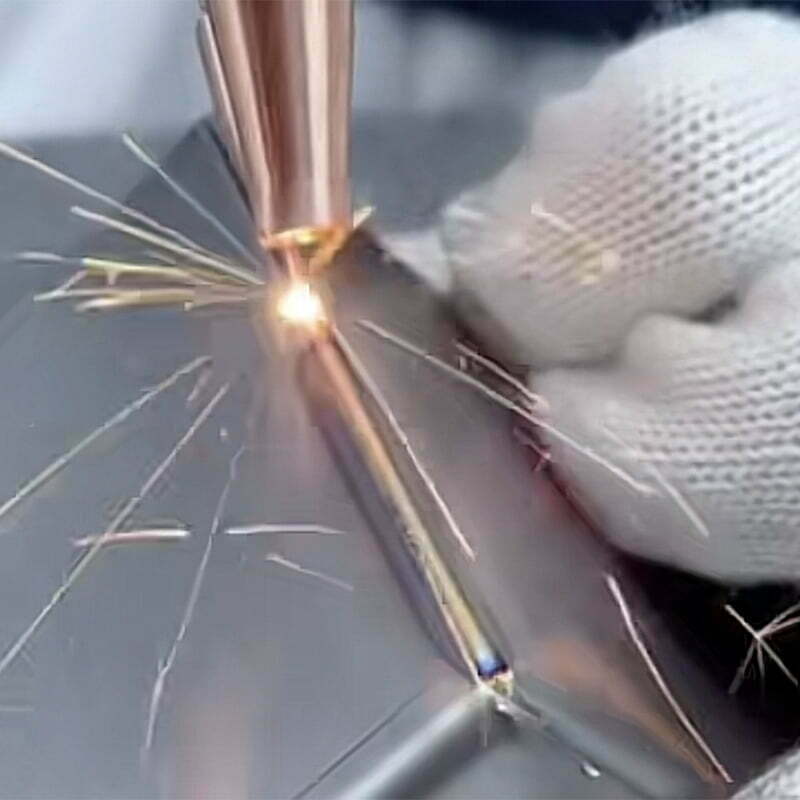

Laser welding is a process that uses high-powered lasers to join two metal components together. This process uses less energy than traditional welding and produces higher quality welds in a fraction of the time. Additionally, this method allows for more precise control over welding parameters such as beam size and shape, power levels, and spot size. This makes it ideal for use in the automotive industry where precision and accuracy are essential for producing safe and reliable cars.

Advantages of Using Laser Welding

One of the biggest advantages of using laser welding in the automotive industry is its speed and efficiency. Because laser welds can be created quickly, manufacturers can reduce production times while still producing high-quality parts. Additionally, because laser welds are more precise than traditional welds, they require less material which translates into lower costs for materials and labor. Finally, because laser welds create stronger bonds between metal components than traditional welds do, they are more reliable which ultimately leads to better performance from cars over their lifetime.

Applications of Laser Welding in Automotive Manufacturing

Laser welding offers many benefits over traditional methods which makes it ideal for use in a variety of applications across the automotive manufacturing process. Some common applications include joining plastic panels to steel frames; connecting body panels; joining chassis components; sealing fuel tanks; attaching door hinges; forming exhaust systems; attaching trim pieces; bonding airbags; fastening brake lines; creating electrical connections; joining battery cells; forming engine components; and much more!

Overall, laser welding has revolutionized the way that cars are manufactured by providing manufacturers with a faster and more efficient method for assembling car parts with greater precision than ever before possible. With its ability to increase production speeds while reducing costs and increasing reliability, it’s easy to see why laser welding has become so popular in the automotive industry today!